This accuracy is also permanent and repeatable throughout the normal life of the system. The accuracy of the system is claimed to be ☐.5 to ☑.5% for most conditions. Inside the upstream bar is another sensing tube (on sizes 50 mm and larger) which is precisely located between orifices to sense the true average head of the entire cross-section of the flow stream, regardless of flow regime.įigure 43. Each of these rings has a cross-sectional area exactly equal to the other annular areas that are detected by each of the other orifices. These orifices are critically located along the bar so that each orifice detects the total pressure in an annular ring. The upstream sensing bar has multiple orifices. The downstream pressure-sensing probe has one orifice which is placed at the centre of the flow stream to measure downstream pressure. It consists of a small pair of sensing probes mounted perpendicularly into the flow stream by means of a conventional threaded fitting. The device is shown in Figures 42 and 43. This difficulty can be avoided by mounting the orifice plate in a vertical run of pipe.Īn interesting adaptation of the pitot, the ‘Annubar’ developed by the Dietrich Standard Corporation, overcomes many of the disadvantages of the simple pitot and obtains a more representative sample of liquid flow than the point reading obtained from the former. These also tend to build up behind an orifice plate and distort the pattern of flow. A very similar problem arises if there are any bubbles of vapor or gas in the flowing fluid when liquid flow is involved.

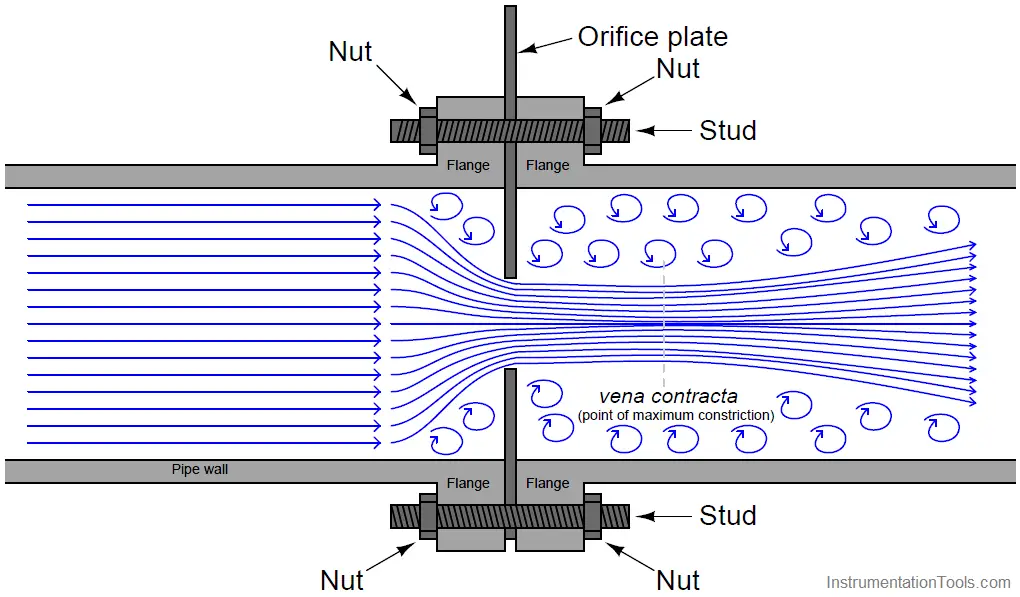

If this hole is close to the bottom of the pipe, solids in the flowing fluid tend to be swept through, and buildup of particles behind the plate is minimized. The latter problem can be minimized by using an orifice plate with an eccentric hole. Other problems with the orifice plate are a gradual change in the discharge coefficient over a period of time as the sharp edges of the hole wear away, and a tendency for any particles in the flowing fluid to stick behind the hole and thereby gradually reduce its diameter as the particles build up. Also, the permanent pressure loss caused in the measured fluid flow is between 50% and 90% of the magnitude of the pressure difference ( P 1– P 2). One limitation of the orifice plate is that its inaccuracy is typically at least ☒% and may approach ±5%.

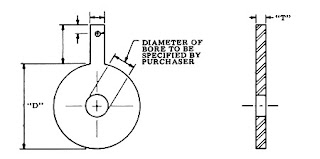

In consequence, they account for almost 50% of the instruments used in industry for measuring volume flow rate. Orifice plates are simple, cheap, and available in a wide range of sizes. The orifice plate is a metal disk with a concentric hole in it, which is inserted into the pipe carrying the flowing fluid. Morris, Reza Langari, in Measurement and Instrumentation (Third Edition), 2021 Orifice plate

0 kommentar(er)

0 kommentar(er)